Picking

This article focuses on using the Operations app. For information on APIs and customizations, see the Picking section.

When you open the Operations app, the first page shown is the picking section. You'll see a list of all the tasks and their current states. By default, they're ordered by date ascending (oldest first) within each status.

Order date versus order created date

The order date is when the customer placed the order in the tenant's shop. It shouldn't be confused with the order created date, which is when the order was created in fulfillmenttools.

Clicking on a task shows all ordered items for that task, including the respective quantity. On the screen that shows all items and on the picking summary screen, the system generates a subtitle for each item based on available attributes if no dedicated subtitle is present.

It's possible to configure picking scanning rules, such as barcode validation or the use of a manual input picker.

Picking sequence

It is possible to sort the pick lines in a picking sequence, which is a numerical order representing the physical location of the item in the picking area. If storage locations are activated for the tenant, the running sequence of the locations is used. Additionally, the picking sequence can be defined in the listing and in the line items of the order. If more than one listing or order line has the same picking sequence number, the system sorts those items by their tenant article ID.

Product attributes in product detail view

Apart from the %%subtitle%% key, only attributes that are supplied with the key category and the value descriptive are displayed.

If no such attributes are defined (and no subtitle is provided), the view remains empty.

Short identifier (short ID)

To identify a task more easily, the system adds a short identifier (shortID). The system generates this identifier from the first letter of the customer's first and last name, along with an incrementing number for each occurrence of that initial combination. This number can have a maximum of two digits (e.g., 99), after which it resets to 1. The identifier is specific to a facility and not unique across the tenant, unlike an order ID.

Example

The identifier for a task that belongs to an order for Jane Doe would be JD1, assuming no other customer at this facility has a first name starting with "J" and a last name starting with "D".

This identifier is also available in the labeling and handover sections. For example, a fulfiller can use this identifier to locate a chosen parcel by writing the identifier on that parcel.

Notifications in Android application

When a new pick job is incoming, the user receives an Android system notification, so the user does not have to check the application periodically.

The notification is related to the facility the user has currently selected in the application. If a user has not selected a facility, the system does not send notifications. Furthermore, the user must be logged in to the application to receive a notification. Notifications are delivered even if the phone's screen is locked. Clicking on the notification leads the user to the list of pick jobs. This approach prevents users from being overwhelmed by notifications.

The notification feature is configurable within the app settings. The sound and banner notifications can be turned on and off. The application saves these settings on the device.

Picking process

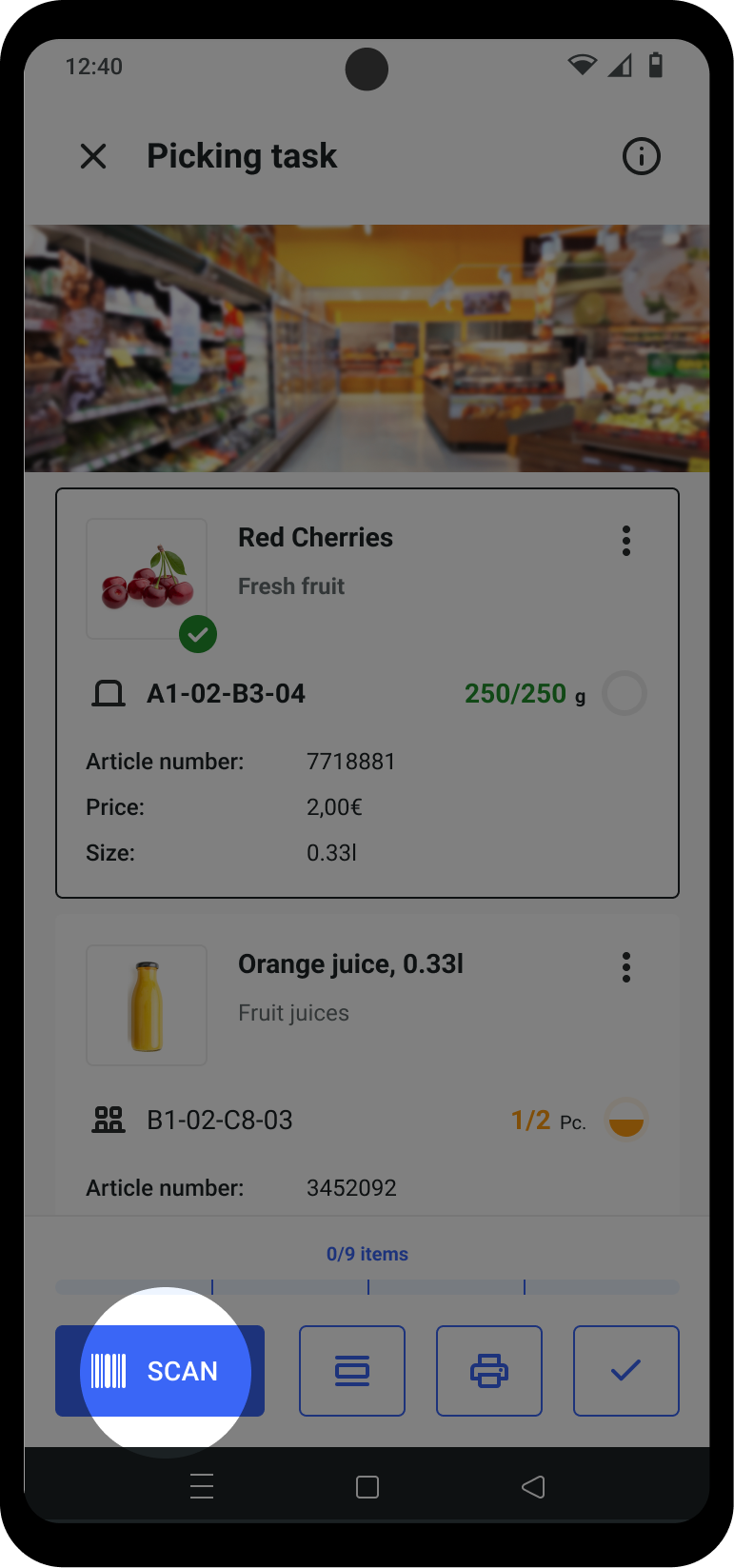

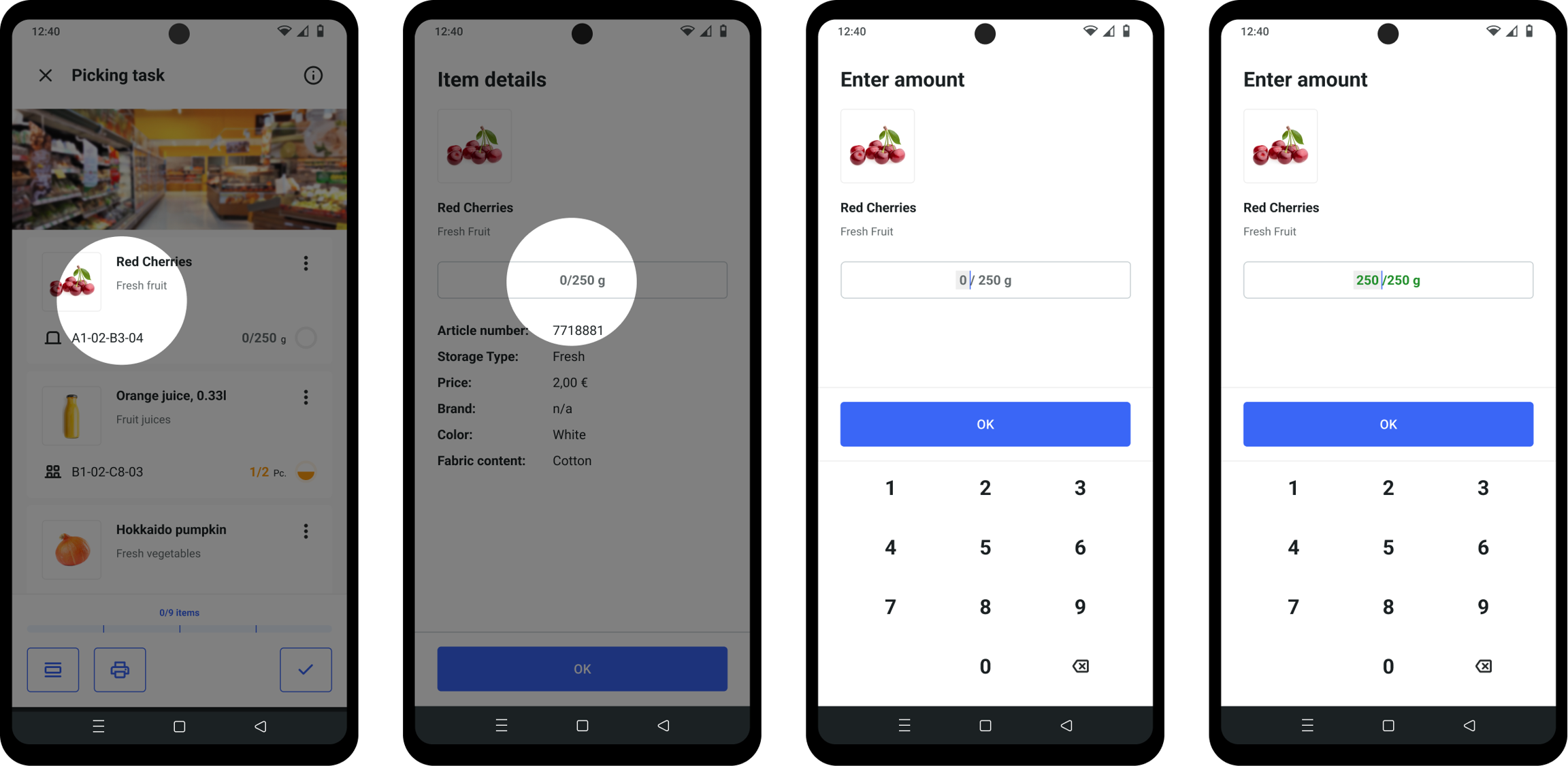

Users can pick each collected line item by either scanning its barcode or manually adding the picked quantity.

Scanning

Users can scan item barcodes using the SCAN button at the bottom of the screen. When using a data collection device, such as a Mobile Data Entry (MDE) device, the device's dedicated scan button can also be used.

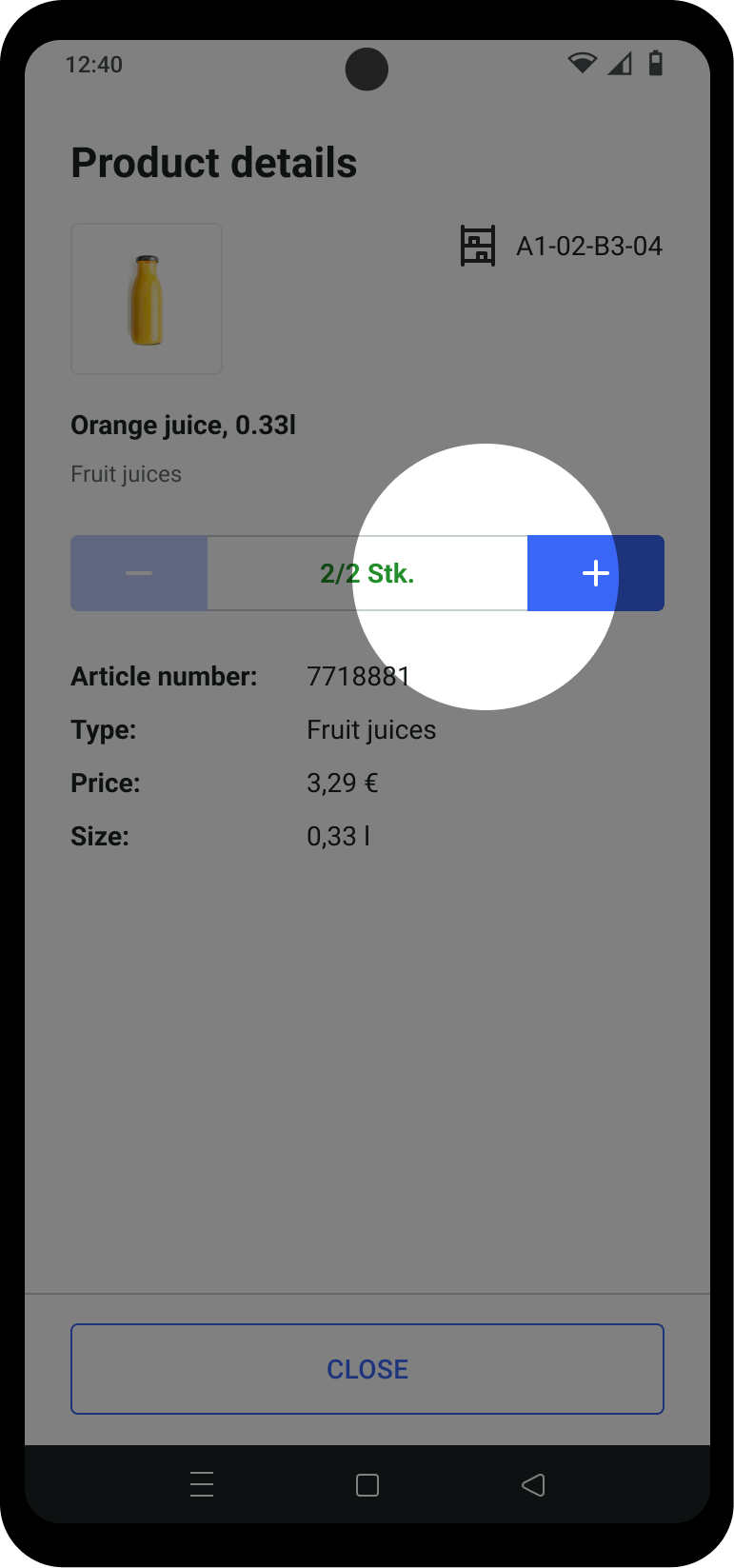

Adding quantities manually

If scanning a barcode is not possible or desired, users can select an item by clicking on it. The user can then manually adjust the quantity using the amount handler and save the change.

Finishing a picking task

Once all available items are picked, the user can complete the picking task by sliding the complete button to the right.

Pausing or interrupting a picking task

During the picking process, the user can pause a picking task by clicking the X in the upper-left corner of the screen. The picked items are saved, allowing the user to resume the task later.

The picking task does not have a specific "paused" status, but the task overview clearly shows that some items have already been picked.

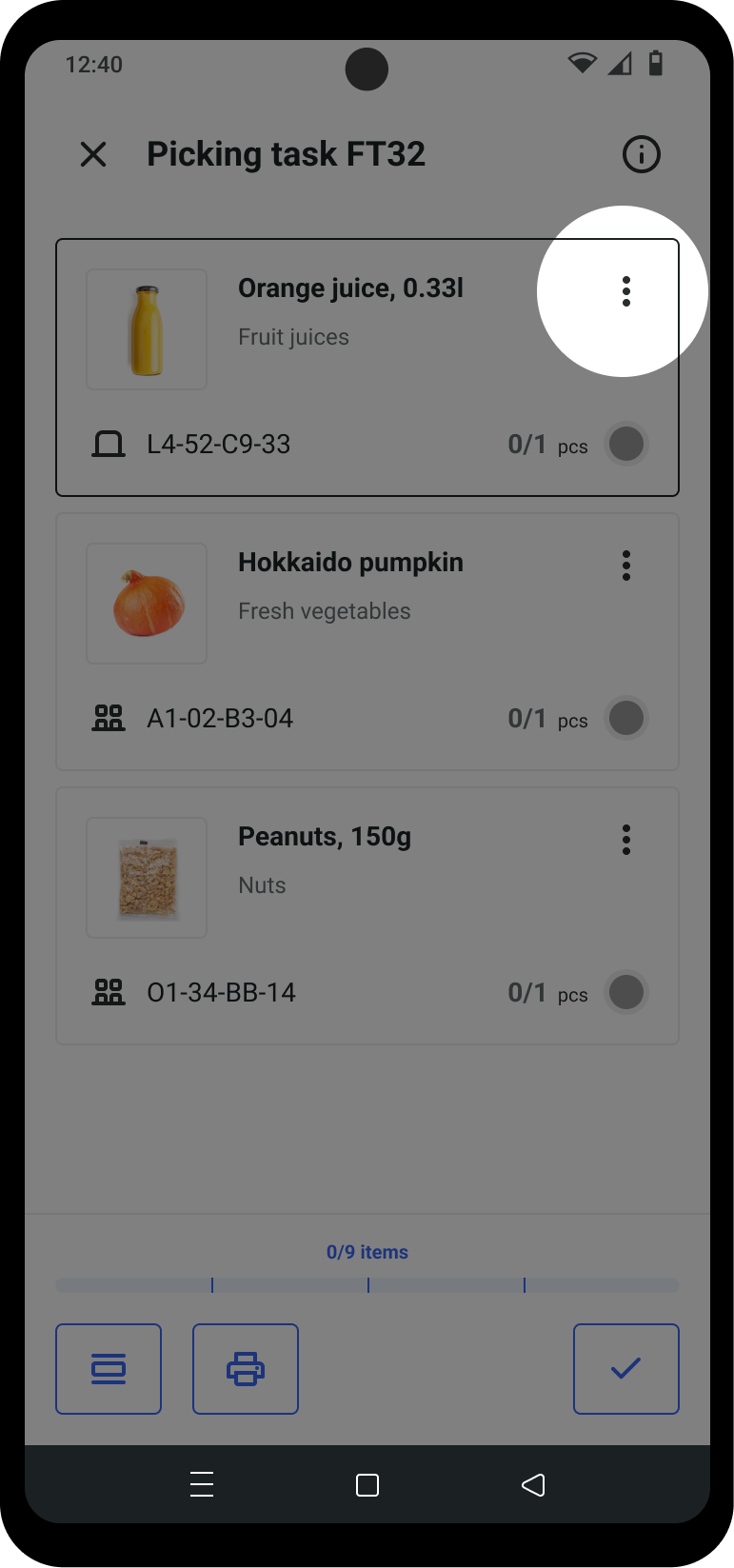

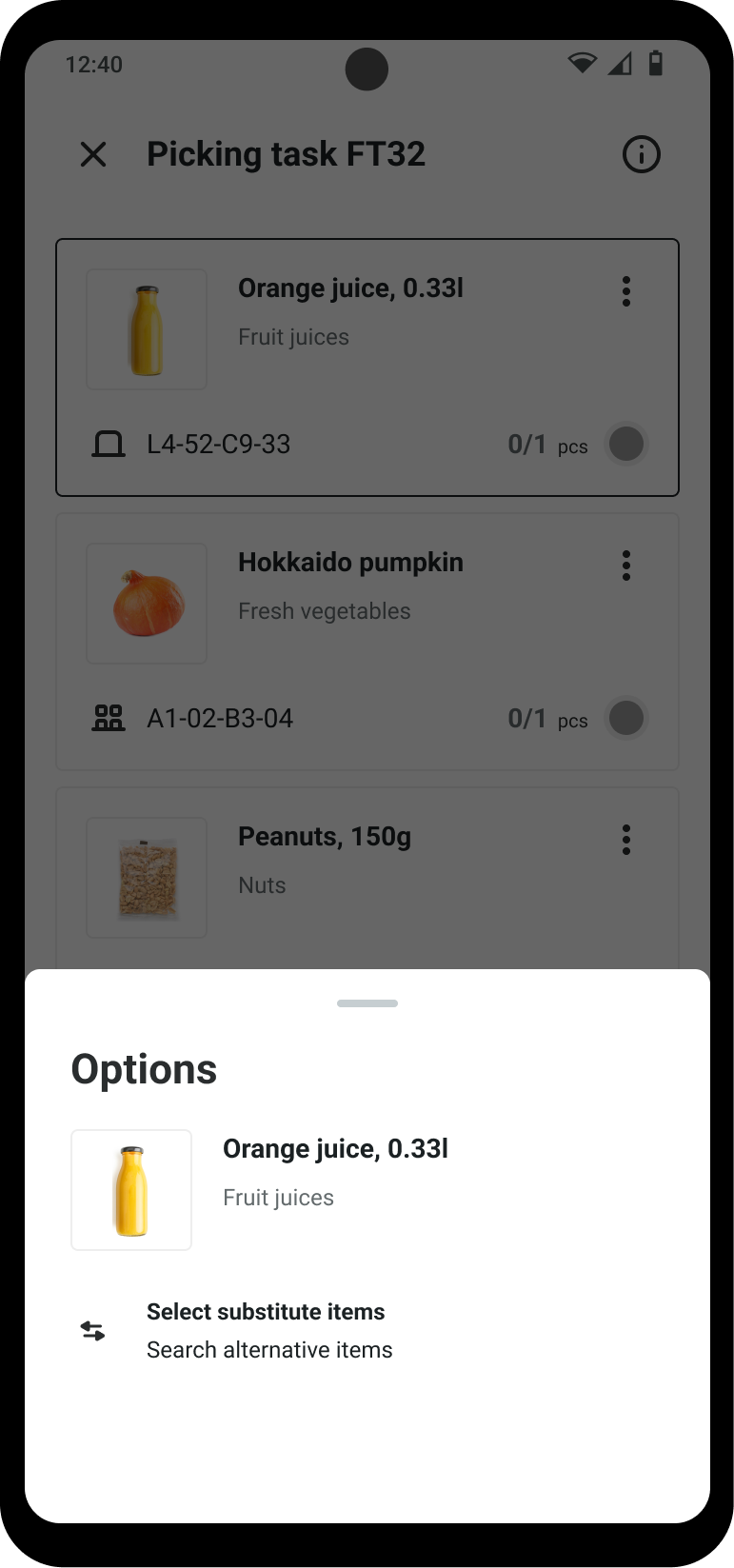

Picking substitute items

Once the task is opened, the user begins picking the ordered items.

If the originally ordered product is unavailable, users can switch to substitute options by pressing the three-dot menu icon (⋮).

Tapping Select substitute items directs the user to the substitute selection screen.

The user selects an available substitute article and enters the correct quantity. The substitute pick is confirmed by tapping CLOSE.

Picking with load units

Once all items for a task have been picked, it is possible to enter the used load units, such as a bag or a box. Load units can be assigned either at the beginning, before picking starts, or at the end, after all items have been picked.

Load unit usage before picking starts:

Load unit usage after picking is completed:

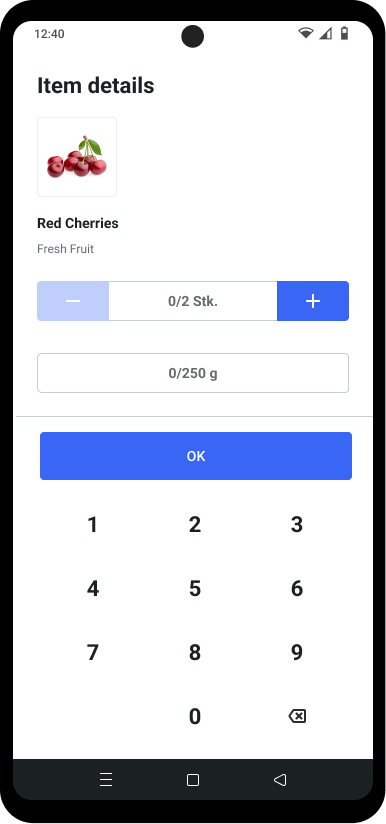

Picking with measurement units

When an item must be picked by weight, length, or a similar criterion, this is specified within the item details. The Operations App automatically displays the required amount.

When a weighted item must be picked, the item should first be weighed, and then the user can enter the weighed amount into the app.

Secondary measurement units

In certain instances, it is necessary to enter additional information about the required amount, such as combining weight with a piece count. For example, when picking a watermelon, the user must specify the number of pieces and the total weight.

Tolerances for measurement units

When a soft or hard tolerance is set for an item, only amounts within that tolerance range can be entered.

Hard tolerance

Hard tolerance prevents over-picking beyond a set percentage. The pickable amount is between the originally ordered amount and the ordered amount plus the tolerance percentage.

Example

1000g of cherries were ordered.

A 20% hard tolerance is set.

The valid picking range is from 1000g to 1200g (1000 + (0.2 * 1000)).

This information is communicated during the picking process.

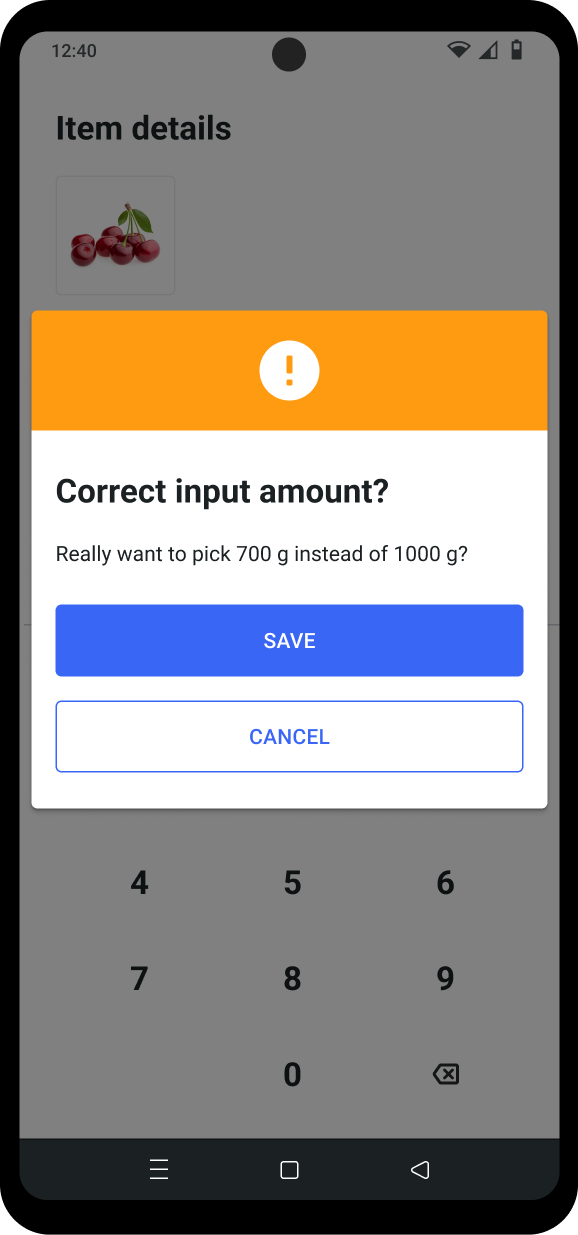

Soft tolerance

Soft tolerance prevents under-picking beyond a set percentage. The pickable amount is between the ordered amount minus the tolerance percentage and the originally ordered amount.

Example

1000g of cherries were ordered.

A 30% soft tolerance is set.

The valid picking range is from 700g to 1000g (1000 - (0.3 * 1000)).

This information is communicated during the picking process.

A combination of hard and soft tolerance is possible.

Reasons for short-picks

If a picking task cannot be completed fully, the system may prompt the user to enter reasons for the short-picks before finishing the task, depending on the configuration.

As the user is about to complete the task, they will be prompted to provide a reason for each line item that was short-picked. This requirement can be optional or mandatory.

Zone picking

When using zone picking, picking tasks can be shown or hidden to the user, depending on the user's assigned zones.

Example

This table provides an at-a-glance view of which tasks are pickable based on the job zones and picker assignments.

A and B

Zone A and B

Yes

A, B, and C

Zone A and B

Yes

C

Zone A and B

No

B and C

Zone A and B

Yes

No assigned zones

N/A

Yes

Last updated