Fulfillment operations pages

This page displays the number and status of pick jobs, pack jobs, and handover jobs in various ways to give insights into store performance.

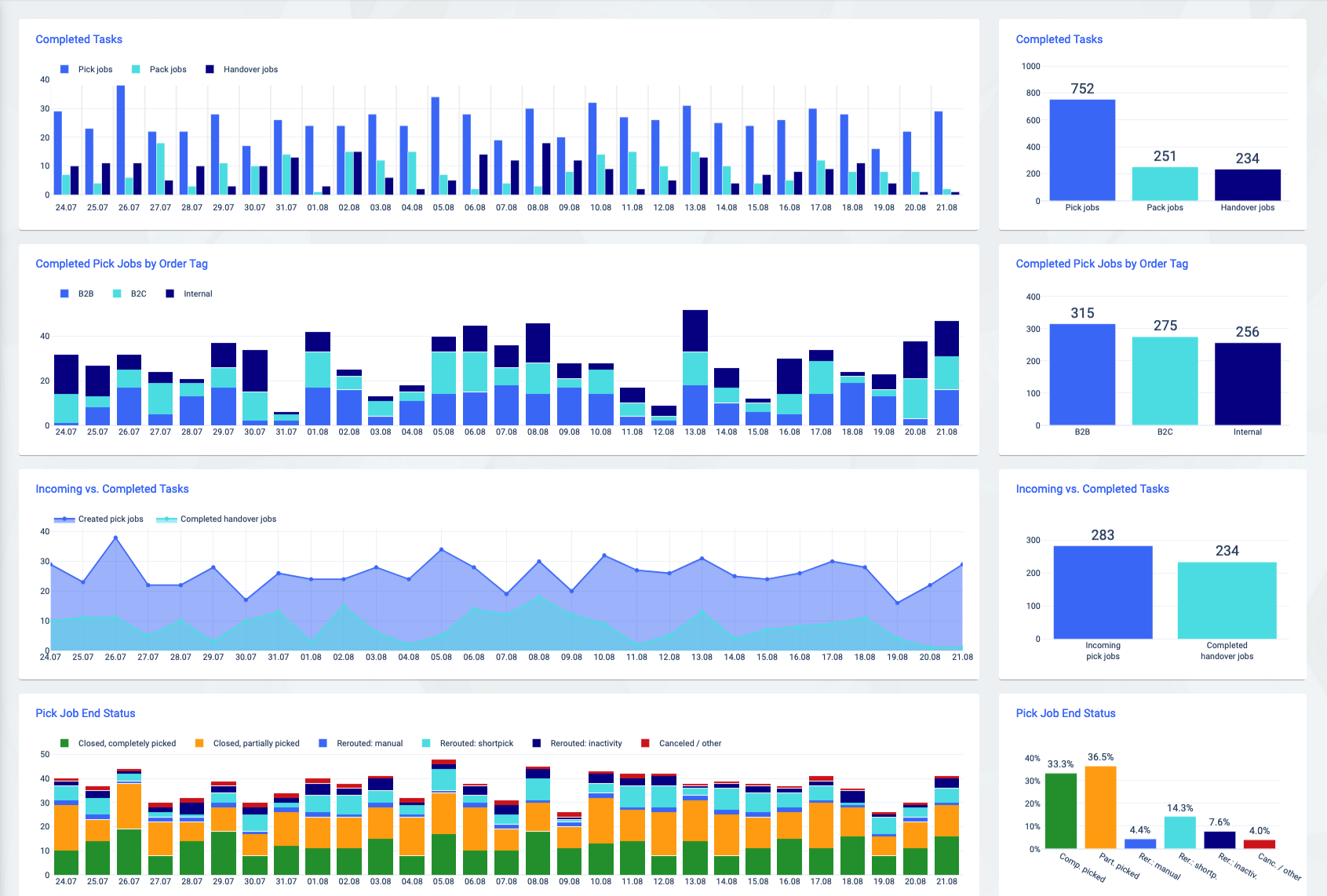

Completed tasks

Completed tasks

This section shows the total number of completed entities by date. Completed means the entities have reached a successful final status. Final statuses that correspond to a failure, such as a cancellation, are not counted.

The assigned date corresponds to the time when the final status was reached. If an entity was reopened and closed again after completion, the system uses the time of the second completion.

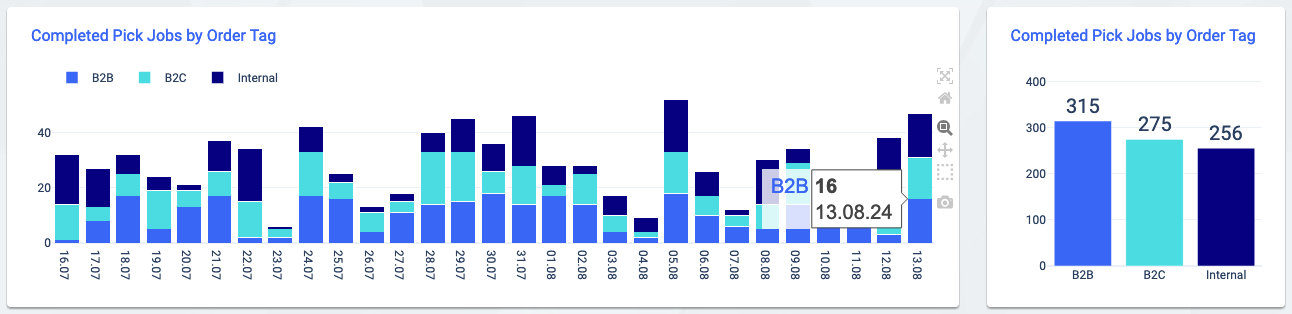

Completed pick jobs by order tag

This chart breaks down the completed pick jobs according to the value of an order tag. In the example below, orders could have an order tag like customer type, with three possible values: B2B, B2C, and Internal. On the selected day, 16 pick jobs were completed for B2B customers.

Since users can create tags freely, the tag key by which the breakdown is made must be configured for the dashboard. Otherwise, this chart is not visible.

Incoming vs. completed tasks

This chart shows created pick jobs and successfully closed handover jobs (status HANDED_OVER) in direct comparison by date to visualize, for example, how order processing is keeping up with the load.

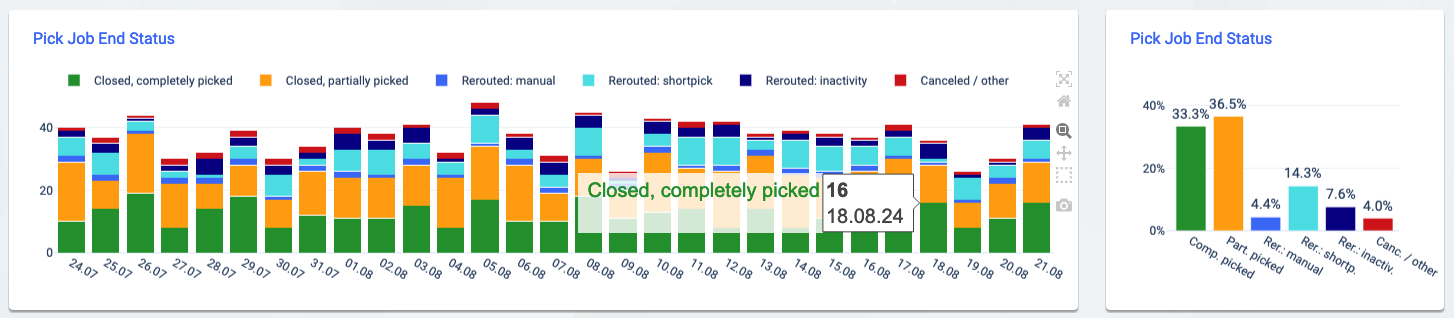

Pick job end status

These charts show the frequency with which pick jobs finished in each status. For pick jobs with a closed status, the chart distinguishes between completely and partially picked. The failed status includes several cases in which a pick job is considered unsuccessful, such as being canceled, aborted, or expired.

In this example, approximately 40 pick jobs finished on November 30, but only 16 of them were picked successfully and completely.

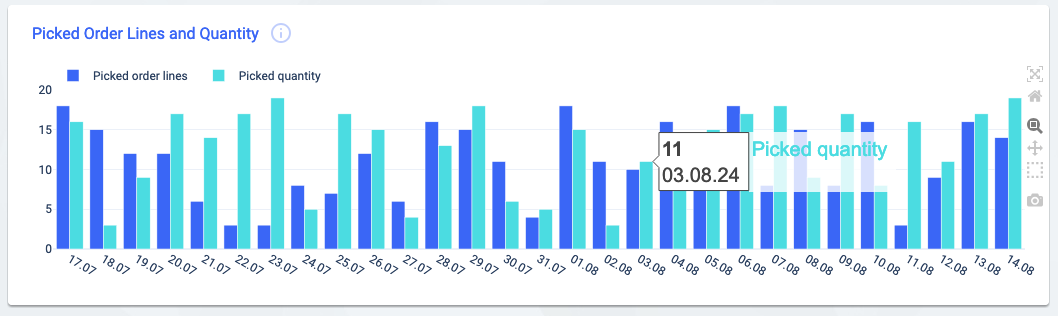

Picked order lines and quantity

This section shows the number of picked order lines and the sum of the picked quantity, both per day and in total. For the assignment to a day, the system uses the time when the respective pick job was closed. Products for which it is known from the measurement unit that they are not counted in pieces are added with a quantity of 1 for each order line.

In this example, 10 order lines with a total quantity of 11 items were picked on August 3. An item could have had a quantity of 500 grams, for example, but this would only have increased the displayed quantity by 1.

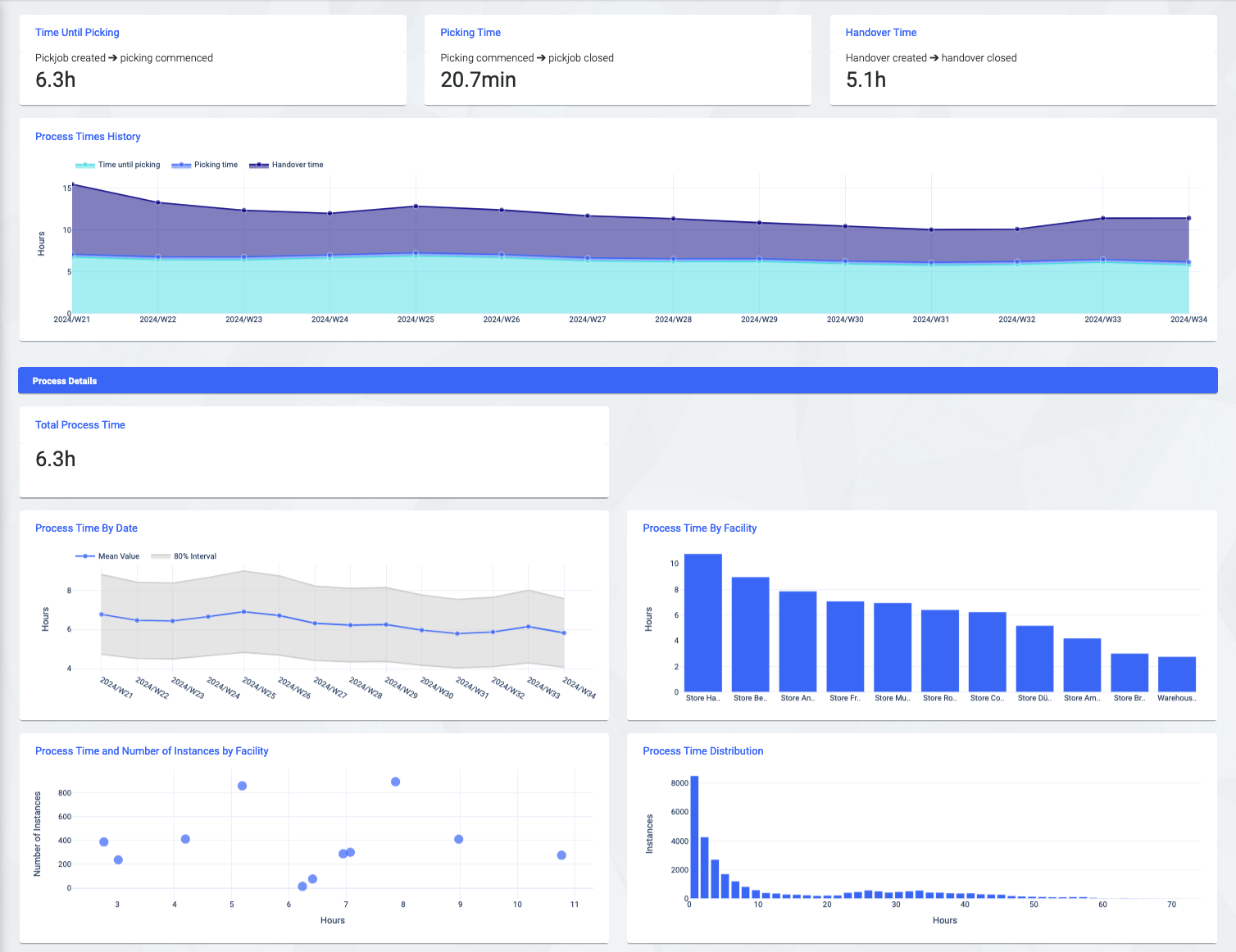

Process times

This page provides detailed information about how long different process steps take within the facilities. The page is divided into two parts: the upper section provides a quick overview of three important durations, while the lower section provides further details on a single selectable duration.

All durations shown here are arithmetic means, with outliers removed on the basis of anomaly detection.

Time until picking, picking time and handover time

The following three durations are shown both aggregated as a total value and by day, week, or month:

Time until picking is the time that elapses between the creation of a

pick joband the first time that picking is started. If apick jobends for any reason, is reopened, and picked again, this is not taken into account here. An analogous restriction applies to the following periods.Picking time is the time that elapses between the first time picking is started and the first time a

pick jobis closed (statusCLOSED).Handover time is the time that elapses between the creation of the

handover joband the first time thehandover jobis closed (statusHANDED_OVER).

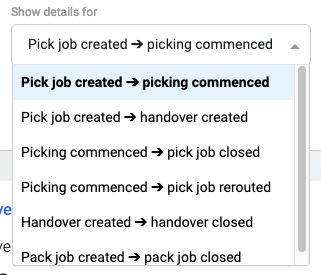

Process details

Because there may be many process times of interest, the details are shown for a single, selected time. The selection is made using the dropdown in the filter bar:

The following graphs then refer to this selected duration.

Total process time

This is the total average calculated over all selected dates and facilities.

Process time by date

In addition to the average value per day, week, or month, the band within which 80% of all cases lie is also shown here. This allows estimating how large typical deviations from the mean value are.

Process time by facility

The average value is given per facility, sorted by the highest value. A maximum of 30 facilities is listed.

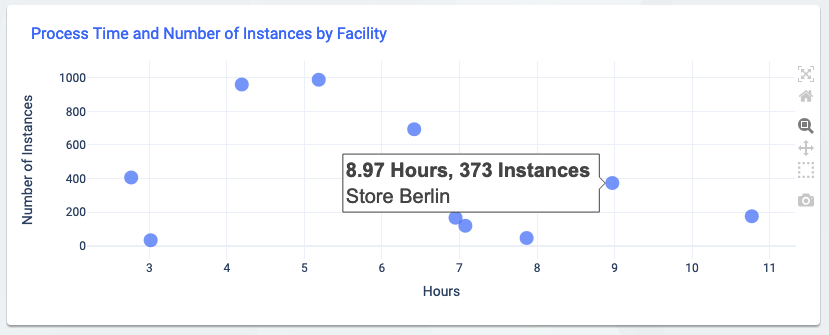

Process time and number of instances by facility

A high process time may not be alarming if the total number of cases is low. For this reason, both values are also plotted against each other in a scatter plot, with each point representing a facility. Data points in the top right-hand corner are of particular interest, as they indicate facilities with both a high duration and a high instance count. In this example, the rather high number of 373 pick jobs in Berlin was created and then picked. The average time between these events was approximately 9 hours, which is in the middle range.

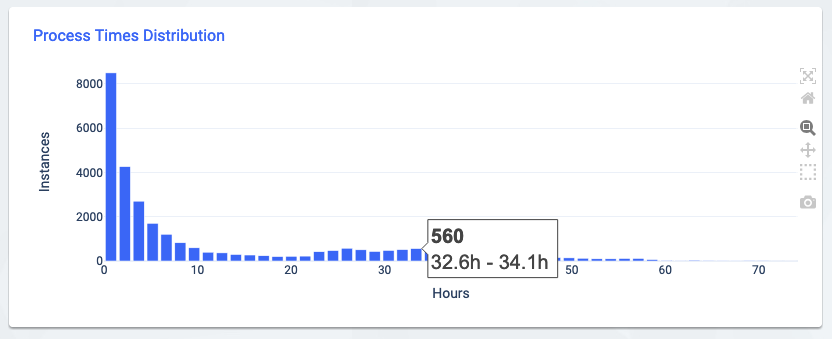

Process time distribution

This graph shows the frequency of cases where a certain amount of time was required. In the example below, it can be seen that the majority of the selected durations were less than 10 hours. In 560 cases, however, the time was approximately 33 hours.

Returns

This page provides various data on returns. As a rule, returns are assigned to the facility that receives them, with the assigned date reflecting the date when the return was initially created in that facility.

Returns

This section shows the number of returns by date. In the example below, users created 8 returns on June 17.

Returns per facility

This table shows the returns and the returned item quantity by facility for the selected time period.

Most frequently returned products

This table lists the most returned products in descending order of total quantity.

Returned items condition

The table shows the number of items for which the condition of the item was specified in the return. The table lists items with a condition in descending order by quantity affected.

Return reasons

The quantities returned for a particular return reason are displayed in tabular form and in a chart plotted by date. The table lists the return reasons in descending order by quantity affected and shows the number of returns containing this reason. The example chart below shows that on November 11, a quantity of 72 was returned with the reason Bad quality. Note that each item in a return can have individual and even multiple reasons. The sum of the quantities shown can therefore be higher than the total quantity returned.

Totally returned value

This table shows the total value of the returned goods in the given time period, separated by currency.

Last updated